CHARACTERISTICS & APPLICATIONS

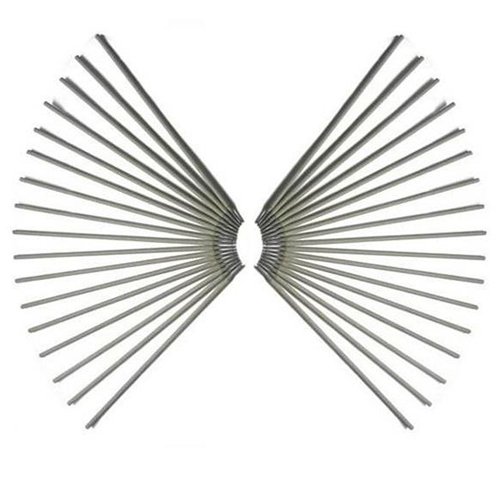

ícel-8010P1 are high cellulose sodium electrodes These electrodes have been designed primarily for welding typical high strength pipe butt joints in the vertical welding position with downward or upward progression. With their cellulosic coverings, they produce deep penetrating, spray-type welding arcs and thin, easily removable slag. This combination is best suited for achieving full penetration and radiographic quality for the downhill welding of butt joints when the axis of the pipe is in horizontal position. While weld metals produced from these electrodes do not have any minimum chemical composition requirements, the supplier must provide sufficient alloying elements to meet the increased mechanical property requirements. Special emphasis must be placed upon the minimum yield strength values since most transmission pipeline materials and systems are designed to yield strength limits. Typical application for E8010-P1 electrodes is the welding of API–5L-X65 piping assemblies.

Storage and Drying Conditions: Ambient temperature

Cellulosic coverings need moisture levels of approximately 3% to 7% for proper operation. Therefore, storage or conditioning above ambient temperature may dry these electrodes too much and adversely affect their operation.

Holding Ovens: Not recommended Drying Conditions: Not recommended.

CHEMICAL COMPOSITION OF UNDILUTED WELD

|

C |

Mn | Si | P | S | Ni | Cr | Mo | V |

Addn Elements |

|

0.20 |

1.20 | 0.60 | 0.030 | 0.030 | 1.00 | 0.30 | 0.50 | 0.10 |

NS |

Single values are maxima, except where specified otherwise.

ALL-WELD-METAL MECHANICAL PROPERTIES (AW)

Preheat and Interpass : 160-190°C | Post weld Heat Treatment : NS°C for 1 Hour(s) The temperature shall be raised at the rate of 85°C to 280°C per hour and allowed to cool at a rate not greater than 200°C per hour, and may be removed from the furnace when the temperature of the furnace has reached 300°C and allowed to cool in still air.

|

Tensile Strength, MPa |

Yield Strength, At 0.2% Offset, MPa | Elongation % |

Charpy V-Notch Impact at -30°C, Joules |

|

550 |

460 | 19 |

27 |

Single values are minimal.

Limit of Moisture Content, % by weight max: NS (Reconditioned) | NS (As Exposed) Diffusible Hydrogen Content Average, Maximum, mL(H2)/100 g Deposited Metal: NS

Welding Considerations

Preheat and interpass minimum temperatures also have a significant effect on the strength levels attained with certain low-alloy steel weld metals. These weld metals are affected by rapid cooling rates which tend to produce more martensitic or bainitic microstructures. These microstructures will often exhibit higher yield and tensile strengths with a decrease in ductility.

The cooling rate can be retarded by utilizing a higher preheat and interpass temperature. The preheat and interpass temperature ranges given herein are adequate for the preparation of the test assemblies. However, in actual production, users are encouraged to test their own procedures to verify that they have selected preheat and interpass temperatures which will produce desirable results in production.

SIZES & CURRENT CONDITIONS (DCEP)

|

DIAMETER, mm |

LENGTH, mm |

Amperes |

|

2.50 |

350 | 40-80 |

| 3.15, 3.20 | 350 |

75-125 |

|

4.00 |

350, 450 | 110-170 |

| 5.00 | 450 |

140-215 |

WARNING: Safety and health information is available from many sources, including, but not limited to Safety and Health Fact Sheets listed in A11.3, ANSI Z49.1 Safety in Welding, Cutting, and Allied Processes published by the American Welding Society, 8669 Doral Blvd., Suite 130, Doral, FL 33166., and applicable federal and state regulations. The Safety and Health Fact Sheets are revised, and additional sheets added periodically.